Have you ever wondered what makes a knife sharp and strong? It all comes down to the metal! Knife making is an art, and the metal you choose is like the canvas for a painter. But picking the perfect metal can be tricky. There are so many types, and each one has its own good and bad points. You want a knife that holds an edge, doesn’t rust easily, and feels good in your hand. It’s a big decision that can make or break your knife.

Choosing the wrong metal can lead to a knife that dulls quickly, chips easily, or even rusts over time. That’s why understanding the different types of knife making metals is so important. We’re going to dive deep into this fascinating world, exploring the strengths and weaknesses of each. By the end of this post, you’ll have a much clearer picture of what makes a great knife blade.

Get ready to learn all about the steels that bring knives to life. We’ll cover everything from basic carbon steel to fancy stainless steel, helping you understand what each one is best for. Let’s get started on your journey to understanding knife making metal!

Our Top 5 Knife Making Metal Recommendations at a Glance

Top 5 Knife Making Metal Detailed Reviews

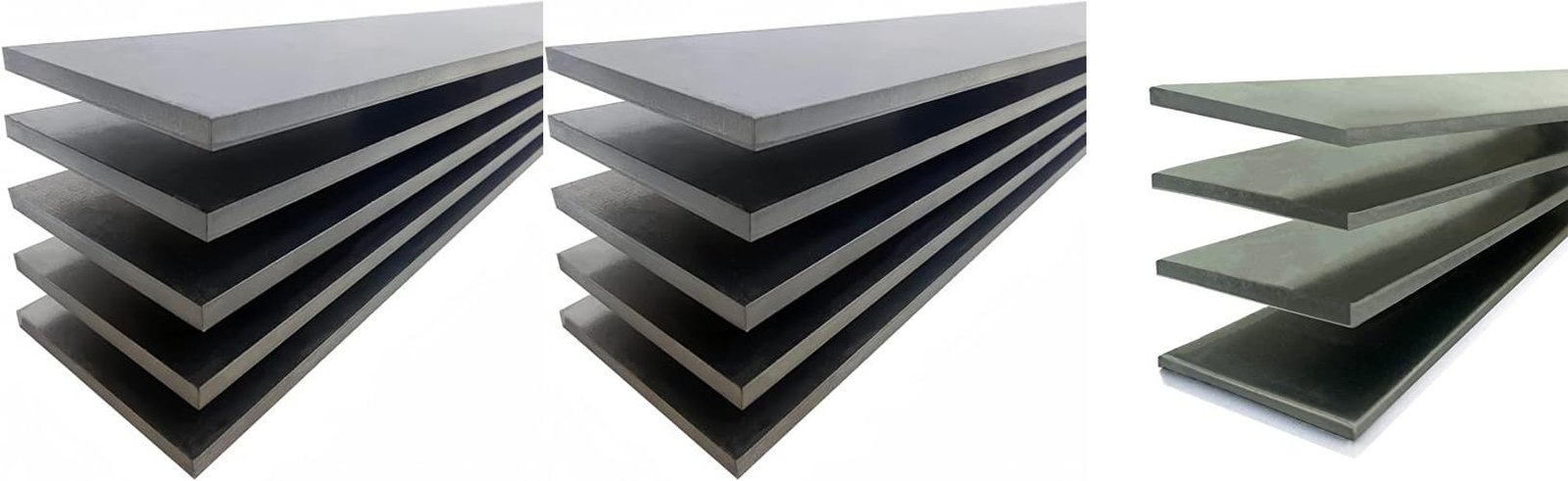

1. 5 Pack 1095 Steel for Knife Making – 12″x1.5″x0.12″ Annealed High Carbon Tool Steel Blanks

Rating: 8.8/10

Are you ready to craft your dream knife? This 5 Pack of 1095 steel is your ideal starting point. These 12″x1.5″x0.12″ annealed high carbon tool steel blanks are precision ground, making them perfect for knife blades and all your DIY projects. Knife makers everywhere trust 1095 steel for its toughness and excellent grinding qualities, and you will too.

What We Like:

- It’s the best choice for knife making, chosen by many famous knife makers.

- The steel is cold rolled and annealed, so it’s easy to work with. This saves you time and effort.

- You get four 12″ x 1.5″ x 0.12″ steel bars in each package. That’s plenty of material for your custom knife.

- The steel comes with three layers of rust-proof packaging, so it arrives in great condition.

- The company offers great after-sales service to make sure you are happy.

What Could Be Improved:

- While the steel is annealed for easier machining, some very intricate designs might still require specialized tools.

- The package contains four bars, which is great, but for very large projects, you might need to purchase additional packs.

This 1095 steel pack offers a fantastic combination of quality and ease of use for aspiring bladesmiths. Get ready to bring your knife-making visions to life!

2. 5 Pack 12″x2″x0.12″ 1095 Steel for Knife Making with Strict Quality Standards

Rating: 9.4/10

Aspiring bladesmiths and seasoned pros, get ready to craft your dream knives! This 5-pack of 12″x2″x0.12″ 1095 steel is specifically chosen for its exceptional quality and ease of use. Renowned by many famous knife makers, this high-carbon steel offers incredible toughness and grinds beautifully, making it the ideal foundation for your handmade DIY creations. Whether you’re a hobbyist just starting out or a professional looking for reliable materials, this steel is designed to help you create knives that last a lifetime.

What We Like:

- This 1095 steel is a top pick for knife making, loved by many well-known manufacturers.

- It’s super tough and grinds easily, perfect for making your own custom knives.

- The steel is annealed, which makes it easier to work with and saves you time and grinding belts.

- Each bar measures 12″ x 1.5″ x 0.12″, giving you plenty of material for your projects.

- It comes with three layers of rust-proof packaging (oil, paper, and bubble wrap) to ensure it arrives in perfect condition.

- The company offers a satisfaction guarantee, ready to help if you’re not happy with your purchase.

What Could Be Improved:

- The product description states the size is 12″x2″x0.12″ in the title, but then specifies 12″ x 1.5″ x 0.12″ in the specifications. This inconsistency could be confusing.

This 1095 steel offers a fantastic starting point for any knife-making project. With its quality and ease of use, you’ll be well on your way to creating a durable, custom knife.

3. 1095 Steel Flat Stock for Knife Making-Annealed High Carbon Steel

Rating: 8.8/10

Unleash your inner craftsman with this 1095 Steel Flat Stock! This pack of four 12-inch by 1.5-inch by 0.12-inch steel bars is designed for serious DIY blade makers. The 1095 steel is the highest carbon grade, meaning you get fantastic results when you heat treat your creations. This steel is cold rolled and annealed, which makes it easier to work with and saves you precious time and sanding belts. Plus, it’s super tough and grinds beautifully, making it ideal for crafting your own blades, knives, hand tools, and even spacers.

What We Like:

- Excellent heat treatment results due to high carbon content.

- Cold rolled and annealed for easier processing and less sanding.

- Super tough and grinds well, perfect for DIY projects.

- Comes in a pack of four, giving you plenty to work with.

- Thoughtfully packaged with three layers of rust-proof protection.

What Could Be Improved:

- Dimensions are fixed; customization might be desired by some.

- While good for DIY, professional-grade finishing might require additional tools.

This 1095 steel flat stock is a top-notch choice for anyone passionate about making their own blades. You’ll love the quality and how it performs during your crafting projects.

4. Ferraycle 4 Pieces 11.5”x1.57”x0.06” 15n20 Steel Flat Stock Bar High Contrast Blade Billets Blanks Annealed High Carbon Steel Barstock for Hobbyist Use Making Forging Carbon Damascus Knives DIY

Rating: 9.3/10

Unleash your inner bladesmith with the Ferraycle 15N20 Steel Flat Stock Bar. This pack of four high-quality steel bars is perfect for hobbyists and DIY enthusiasts looking to craft their own knives, tools, and more. The 15N20 steel is a popular choice for creating beautiful Damascus patterns, and it’s also great for making durable, sharp blades.

What We Like:

- You get four pieces of steel, which is plenty for several projects.

- The size is just right for making knives and other handy items.

- This steel is known for its durability and resistance to rust and wear.

- It’s ideal for forging unique Damascus steel patterns when combined with other high-carbon steels.

- The steel has good toughness and sharpens well.

What Could Be Improved:

- The description mentions that if etching doesn’t show a bright contrast, it might be a polishing issue, meaning extra care is needed in the finishing steps.

This 15N20 steel flat stock offers a fantastic starting point for your forging and knife-making adventures. Dive into your next DIY project with confidence using this reliable and versatile material.

5. 5 Pack 1095 Steel Flat Stock Bar

Rating: 8.9/10

This 5 Pack of 1095 Steel Flat Stock Bars is a fantastic choice for anyone looking to craft their own knives or other DIY projects. Each bar measures 12 inches long, 2 inches wide, and 1/8 inch thick. Made from premium 1095 high carbon steel, these bars offer great hardness and wear resistance. They also have good elasticity and toughness, making them reliable for all sorts of creations.

What We Like:

- Made from high-quality 1095 steel, known for its toughness and ability to hold a sharp edge.

- Versatile for knife making, tool crafting, spacers, and other DIY projects.

- Comes in a convenient 5-pack, offering good value for hobbyists and professionals.

- Cold-rolled and annealed for easier machining and less sanding time.

- Securely packaged to arrive in good condition.

- The company offers good support if you have any issues with your order.

What Could Be Improved:

- While the steel is good, some users might prefer a slightly thicker or wider bar for specific larger projects.

- The “strict quality standards” are mentioned, but more specific details on tolerances or testing could be beneficial for absolute perfectionists.

This steel is a solid foundation for your next project. It’s a great material for bringing your creative knife-making ideas to life.

Choosing the Right Knife Making Metal: Your Guide to a Sharp Decision

Making your own knife is a rewarding project. You get a tool that’s perfectly suited to your needs. But the most important part of any knife is its metal. The right metal makes a knife sharp, strong, and long-lasting. This guide helps you pick the best metal for your knife-making adventure.

Key Features to Look For

When you’re looking at metals for knife making, consider these important features:

- Hardness: This tells you how well the metal holds an edge. A harder metal stays sharp longer.

- Toughness: This is how strong the metal is. A tough metal won’t chip or break easily, even when you use it hard.

- Corrosion Resistance: This means how well the metal fights off rust. Stainless steel is good at this.

- Ease of Sharpening: Some metals are easier to sharpen than others.

- Edge Retention: This is how long the knife’s edge stays sharp.

Important Materials

Several types of steel are popular for making knives. Each has its own strengths.

Carbon Steel

Carbon steel is a classic choice. It’s strong and holds a very sharp edge. It’s also easy to work with and sharpen. However, carbon steel can rust if you don’t take care of it. You need to oil it and dry it well after use.

Stainless Steel

Stainless steel is loved for its rust resistance. It’s a great option if you want a low-maintenance knife. Many stainless steels are also hard and hold a good edge. Some can be a bit harder to sharpen than carbon steel.

Tool Steel

Tool steels are designed for tough jobs. They are very hard and can keep an edge for a long time. They are often used for knives that need to be extremely durable. Tool steels can be more difficult to grind and sharpen.

Factors That Improve or Reduce Quality

The quality of your knife metal can change based on a few things.

Heat Treatment

This is a very important step. Proper heat treatment makes the steel hard and tough. If it’s not done right, the metal won’t perform well. It might be too soft or too brittle.

Alloying Elements

Adding other metals to steel, like chromium or vanadium, changes its properties. These additions can make the steel stronger, more rust-resistant, or better at holding an edge.

Manufacturing Process

How the steel is made matters. High-quality steel is made with careful processes. This ensures it has the right structure and fewer impurities.

User Experience and Use Cases

The best metal for you depends on how you plan to use your knife.

- Kitchen Knives: Stainless steel is a good choice here because it resists stains and is easy to clean. Carbon steel can also work if you keep it dry.

- Outdoor and Survival Knives: These knives need to be tough and hold an edge well. Carbon steel or certain tool steels are often preferred.

- Everyday Carry (EDC) Knives: You want a balance of edge retention, toughness, and corrosion resistance. Many stainless steels fit this need.

Choosing the right knife-making metal is the first step to a great knife. Think about what you want your knife to do, and pick the metal that best fits those needs.

Frequently Asked Questions (FAQ)

Q: What is the easiest metal for a beginner to use?

A: For beginners, simple carbon steels like 1075 or 1084 are often recommended. They are forgiving and easier to heat treat.

Q: Does stainless steel rust?

A: While called “stainless,” most stainless steels can still rust under certain conditions. They are much more resistant to rust than carbon steels.

Q: How does the hardness of steel affect a knife?

A: Harder steel holds a sharper edge for longer. However, very hard steel can sometimes be more brittle and prone to chipping.

Q: What is “grain” in knife steel?

A: The “grain” refers to the microscopic structure of the steel. A finer grain usually means a stronger, tougher blade that can be sharpened to a finer edge.

Q: Is it better to use a harder or softer steel?

A: It depends on the use. Harder steel keeps an edge longer but can chip. Softer steel is tougher and less likely to break but dulls faster.

Q: What is the difference between steel and iron for knives?

A: Steel is an alloy of iron and carbon. The carbon gives steel its strength and hardness, which iron alone doesn’t have.

Q: Can I use scrap metal to make a knife?

A: While possible, using unknown scrap metal is not recommended for good knife making. It’s hard to know its exact composition and how it will perform.

Q: What does “tempering” mean in knife making?

A: Tempering is a heat treatment process done after hardening. It reduces brittleness and increases toughness, making the blade more durable.

Q: How much does knife making metal cost?

A: The cost varies greatly. Simple carbon steel might be inexpensive, while high-performance stainless or tool steels can be more costly.

Q: Where can I buy knife making metal?

A: You can buy knife making metal from specialized online suppliers, metal supply stores, or some woodworking and crafting shops.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Larry Fish, the mind behind MyGrinderGuide.com.. With a passion for all things kitchen appliances, I created this blog to share my hands-on experience and expert knowledge. Whether it’s helping you choose the right tools for your culinary adventures or offering tips to make your kitchen more efficient, I’m here to guide you. My goal is to make your time in the kitchen not only easier but also enjoyable! Welcome to my world of kitchen mastery!