Imagine holding a knife that never rusts, stays sharp for ages, and feels perfectly balanced in your hand. That’s the dream for any knife maker, right? But getting there isn’t always easy. Choosing the right stainless steel for your project can feel like navigating a maze. You want a blade that performs beautifully, but with so many different types of steel out there, how do you know which one is best?

This confusion can lead to frustration. You might end up with a knife that dulls too quickly, gets stained easily, or is too difficult to work with. That’s why understanding stainless steel is so important for anyone serious about knife making. It’s the heart of your creation, and getting it right makes all the difference.

In this post, we’re going to cut through the jargon and explain the key things you need to know about stainless steel for knives. We’ll explore what makes some steels better than others, what to look for, and how to avoid common mistakes. By the end, you’ll have the knowledge to confidently pick the perfect stainless steel for your next knife-making adventure.

Our Top 5 Stainless Steel For Knife Making Recommendations at a Glance

Top 5 Stainless Steel For Knife Making Detailed Reviews

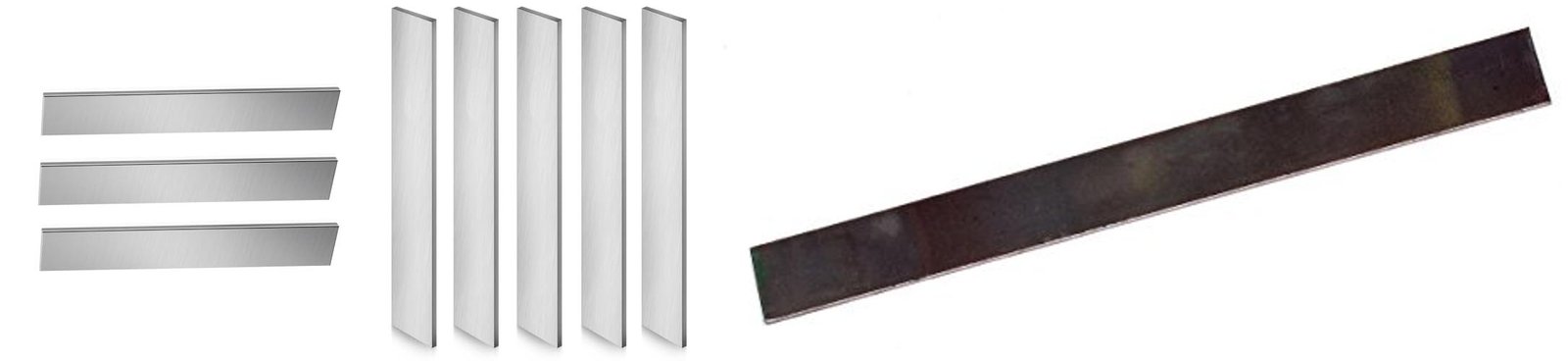

1. 3 Pack 15N20 Steel for Knife Making – 12″x1.5″x1/8″ 15N20 Steel Flat Stock Knife Blanks for Knife Making DIY

Rating: 9.2/10

Are you ready to craft your own custom knives? This 3 Pack of 15N20 Steel Flat Stock Knife Blanks is your perfect starting point. Each blank measures 12 inches long, 1.5 inches wide, and 1/8 inch thick, giving you ample material to design and create a variety of knife styles. Whether you’re a seasoned bladesmith or a beginner looking to dive into the world of DIY knife making, these high-quality steel blanks are designed to make your project a success.

What We Like:

- High-Quality Material: 15N20 steel is known for its excellent strength and resistance to wear and rust. It’s also very easy to work with, making it ideal for knife making.

- Generous Size: The 12″ x 1.5″ x 1/8″ dimensions provide plenty of material for creating a good range of knife shapes and sizes.

- Excellent Rust Protection: The steel comes coated in rust-proof oil and is wrapped in special paper. It’s then sealed in a waterproof bag, greatly reducing the chance of rust during shipping and storage.

- Versatile Applications: While perfect for knives, this steel is also used for saw blades, springs, and other mechanical parts, showing its durability and adaptability.

- Hassle-Free Guarantee: The company stands behind its product. If you’re not happy or find any rust, they promise a replacement or a full refund.

What Could Be Improved:

- Limited Information on Heat Treatment: While the product mentions heat treatment can adjust properties, more specific guidance for 15N20 steel would be helpful for beginners.

This 3-pack of 15N20 steel is a fantastic investment for any aspiring knife maker. Its quality materials and thoughtful packaging ensure you get a great product ready for your creative touch.

2. 5 Pack 1095 Steel Flat Stock Bar

Rating: 9.0/10

Unleash your inner craftsman with the ANTALENA 5 Pack of 1095 Steel Flat Stock Bars. These 12-inch by 2-inch by 1/8-inch bars are made from premium 1095 high-carbon steel, a material trusted by many knife makers. It’s known for being tough, holding an edge well, and being easy to work with. Whether you’re a seasoned pro or just starting out in DIY projects, these steel bars offer a fantastic foundation for your creations.

What We Like:

- Made from high-quality 1095 steel, offering excellent hardness and wear resistance.

- Versatile for knife making, tool crafting, and other DIY projects.

- Each pack includes 5 bars, each measuring 12” x 2” x 1/8”.

- Cold rolling and annealing make the steel easier to machine and save you time.

- The company provides good support if you have any issues.

What Could Be Improved:

- While described as securely protected, there’s always a slight risk of damage during shipping for metal products.

- The product description focuses heavily on knife making; other potential uses could be highlighted more.

This steel stock is a reliable choice for anyone looking to create durable and high-quality items. With its excellent properties and thoughtful preparation, it’s ready for your next project.

3. 440C Stainless Steel Barstock for Knife Making – 1/8″ x 1-1/4″ x 12″

Rating: 9.2/10

This premium grade 440C stainless steel barstock is a fantastic choice for anyone looking to make their own knives. It’s a high-quality material designed specifically for knife blades, offering a great balance of properties for a wide range of uses. The dimensions are convenient for many knife designs, and its composition makes it a reliable performer.

What We Like:

- It’s a premium grade martensitic stainless steel, perfect for making tough knife blades.

- The steel has a good amount of carbon (1.1%) and chromium (17%), which helps it hold a sharp edge and resist rust.

- The dimensions (1/8″ x 1-1/4″ x 12″) are a useful size for many different knife projects.

- It offers high strength, so your handmade knives will be durable.

- It has moderate corrosion resistance, meaning it won’t rust easily with normal use.

- The steel provides good hardness and wear resistance, so the blade stays sharp longer.

What Could Be Improved:

- While it has moderate corrosion resistance, it’s not as resistant as some higher-end stainless steels.

- It can be a bit harder to work with than softer steels, which might be a challenge for beginners.

This 440C stainless steel barstock is a solid foundation for crafting durable and sharp knives. It’s a great material for makers who want reliable performance and good value.

4. Patriot Steel 1095 High Carbon Knife Making & Forging Steel – Cold Rolled Annealed Flat Bars & Blanks – Knifemakers

Rating: 9.1/10

Get ready to forge amazing knives with Patriot Steel’s 1095 High Carbon Knife Making & Forging Steel. This pack comes with four 12-inch by 1.5-inch by .125-inch cold-rolled annealed flat bars. They are milled right here in the USA. This steel is perfect for anyone making knives, from beginners to pros.

What We Like:

- Made from USA-milled 1095 high carbon steel for great performance.

- It’s already annealed, so you can start forging right away. This saves you time and effort.

- Great for all kinds of knives, from custom blades to starter projects.

- The steel has steady sizes and hardness, so you know what you’re getting.

- It’s a reliable supply from a trusted American company.

What Could Be Improved:

- The .125-inch thickness might be a bit thin for some very heavy-duty knife projects.

- While annealed, some users might prefer a slightly softer steel for initial shaping.

This Patriot Steel pack is a solid choice for anyone serious about knife making. You’ll get consistent, high-quality material to bring your blade designs to life.

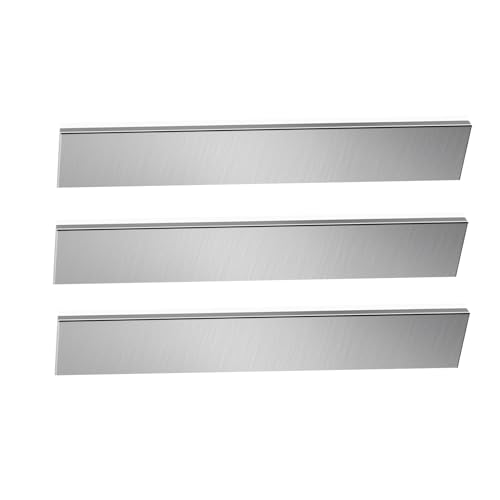

5. 4 Pack 12″x1.5″x0.12″ 1095 Steel for Knife Making with Strict Quality Standards

Rating: 9.3/10

Are you ready to craft your own amazing knives? This 4-pack of 1095 steel is exactly what you need. It’s a top choice for knife makers, both pros and beginners. This steel is known for being super tough and easy to grind. It’s perfect for making handmade knives that are built to last. You’ll love how well it works for your DIY projects.

What We Like:

- It’s the “BEST CHOICE FOR YOUR KNIFE,” trusted by many famous knife makers.

- The steel is “COLD ROLLED & ANNEALED,” making it easier to work with and saving you time and resources.

- You get four bars of “1095 Steel Bar Stock,” each measuring 12″ x 1.5″ x 0.12″, giving you plenty of material.

- “PERFECT PACKAGING” with three layers of protection keeps your steel safe from rust and damage.

- The company offers great “AFTER-SALES SERVICE,” ensuring you’re happy with your purchase.

What Could Be Improved:

- While the steel is annealed for better machinability, some very intricate designs might still require advanced techniques.

- The thickness of 0.12″ is standard, but for some specialized knife types, thicker or thinner stock might be preferred.

This 1095 steel set is a fantastic starting point for anyone passionate about knife making. Get ready to create something truly special!

Choosing the Best Stainless Steel for Your Knife Project

Making your own knife is a rewarding hobby. You get a tool that’s perfectly suited for your needs. The most important part of any knife is the steel it’s made from. Stainless steel is a popular choice for many knife makers. It resists rust and stays sharp. This guide will help you pick the right stainless steel for your next project.

Key Features to Look For

When you’re buying stainless steel for knife making, several features matter a lot. These features affect how easy the steel is to work with and how well your finished knife will perform.

- Hardness: This is how well the steel resists scratching and wear. Harder steel holds an edge longer.

- Toughness: This is how well the steel resists breaking or chipping. A tough knife can handle hard use.

- Corrosion Resistance: Stainless steel is known for this. It means the steel won’t rust or stain easily.

- Edge Retention: This is how long the knife stays sharp. Good edge retention means you won’t have to sharpen it often.

- Grindability: This is how easy it is to shape and sharpen the steel. Some steels are harder to work with than others.

Important Materials in Stainless Steel

Stainless steel gets its special properties from different elements mixed into it. Understanding these helps you choose.

- Chromium: This is the key ingredient that makes steel “stainless.” It forms a protective layer on the surface that stops rust. Most stainless steels have at least 11% chromium.

- Carbon: Carbon makes steel stronger and harder. More carbon usually means a harder blade that can hold a sharp edge.

- Molybdenum: This element helps the steel resist wear and corrosion. It also helps the steel stay hard at high temperatures.

- Vanadium: Vanadium forms small, hard particles in the steel. These particles improve wear resistance and toughness.

- Nickel: Nickel makes stainless steel tougher and more resistant to corrosion. It also helps with its appearance.

Factors That Improve or Reduce Quality

Not all stainless steels are made equal. Certain things can make a steel better or worse for knife making.

- Heat Treatment: How the steel is heated and cooled is very important. Proper heat treatment makes the steel reach its best hardness and toughness. Poor heat treatment can ruin even the best steel.

- Alloy Composition: The exact mix of elements matters. A well-balanced mix creates a steel with great all-around performance. Too much or too little of an element can cause problems.

- Manufacturing Process: How the steel is made affects its purity and consistency. Clean steel with few impurities is better.

- Grain Structure: The tiny crystals inside the steel affect its strength and how it sharpens. A fine grain structure is usually best.

User Experience and Use Cases

The stainless steel you choose will greatly impact how your knife feels and performs.

- Everyday Carry (EDC) Knives: For EDC knives, you want a good balance of sharpness, toughness, and corrosion resistance. Steels like 154CM or CPM-S30V are excellent choices. They hold an edge well and resist rust.

- Kitchen Knives: Kitchen knives need to be very sharp and easy to resharpen. High-carbon stainless steels like VG-10 or AEB-L are popular. They offer great cutting performance and good corrosion resistance.

- Outdoor and Survival Knives: These knives need to be very tough and reliable. They must handle rough tasks. Steels like D2 (though it’s semi-stainless) or tougher stainless alloys are good. They can take a beating.

- Tactical Knives: Tactical knives often require extreme hardness for piercing and a strong edge. Some high-end stainless steels offer this.

Choosing the right stainless steel is a big step in knife making. Think about what you want your knife to do. Then, look for steel that has the features you need. With the right steel, you can create a knife that lasts for years.

Frequently Asked Questions (FAQ) about Stainless Steel for Knife Making

Q: What is the most important thing to consider when buying stainless steel for a knife?

A: The most important thing is to know what you will use the knife for. This helps you choose steel with the right balance of hardness, toughness, and corrosion resistance.

Q: Is it okay to use any stainless steel for knife making?

A: No, not all stainless steels are good for knives. Some are too soft or don’t hold an edge well. You need specific knife-making grades of stainless steel.

Q: What does “stainless” really mean for steel?

A: “Stainless” means the steel resists rust and stains. This is because it has a good amount of chromium in it.

Q: How does heat treatment affect stainless steel quality?

A: Heat treatment is very important. It makes the steel hard enough to hold an edge and tough enough not to break. Doing it wrong can ruin the steel.

Q: Which stainless steels are best for beginners?

A: For beginners, steels like 440C or 8Cr13MoV are often recommended. They are easier to work with and still offer good performance.

Q: What is the difference between high-carbon stainless steel and regular stainless steel?

A: High-carbon stainless steel has more carbon. This makes it harder and better at holding a sharp edge, similar to carbon steel, but it still resists rust.

Q: Can I make a knife from stainless steel cutlery?

A: While some cutlery is made from good steel, it’s often difficult to tell the exact grade. Buying steel specifically made for knife making is usually better for predictable results.

Q: How do I know if a stainless steel will be tough enough?

A: Toughness often comes from a good balance of elements like chromium, nickel, and molybdenum, along with proper heat treatment. Manufacturers usually list toughness ratings or properties.

Q: Is more chromium always better for stainless steel?

A: Not necessarily. While chromium provides corrosion resistance, too much can sometimes make the steel brittle. The right amount depends on the other elements in the alloy.

Q: Where can I buy good quality stainless steel for knife making?

A: You can buy it from specialized knife-making supply stores online or sometimes from metal suppliers who cater to hobbyists.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Larry Fish, the mind behind MyGrinderGuide.com.. With a passion for all things kitchen appliances, I created this blog to share my hands-on experience and expert knowledge. Whether it’s helping you choose the right tools for your culinary adventures or offering tips to make your kitchen more efficient, I’m here to guide you. My goal is to make your time in the kitchen not only easier but also enjoyable! Welcome to my world of kitchen mastery!