Ever wondered what makes a knife blade sharp and strong? It’s all about the steel! Choosing the right steel for a knife blade can feel like a puzzle. There are so many types, and each one does different things. Some steels keep an edge for a long time, while others are tougher and won’t break easily. It’s tricky to know which is best for your needs.

This confusion can lead to a knife that dulls quickly or even chips. But don’t worry! By understanding the basics of knife steel, you can pick a blade that works perfectly for you, whether you’re cutting food in the kitchen or tackling outdoor adventures. This post will break down the important stuff about knife steels so you can make a smart choice.

Keep reading to learn what makes different steels special and how to find the perfect steel for your next knife blade. We’ll explore the key features that matter and what they mean for your cutting tasks.

Our Top 5 Steel For Knife Blades Recommendations at a Glance

Top 5 Steel For Knife Blades Detailed Reviews

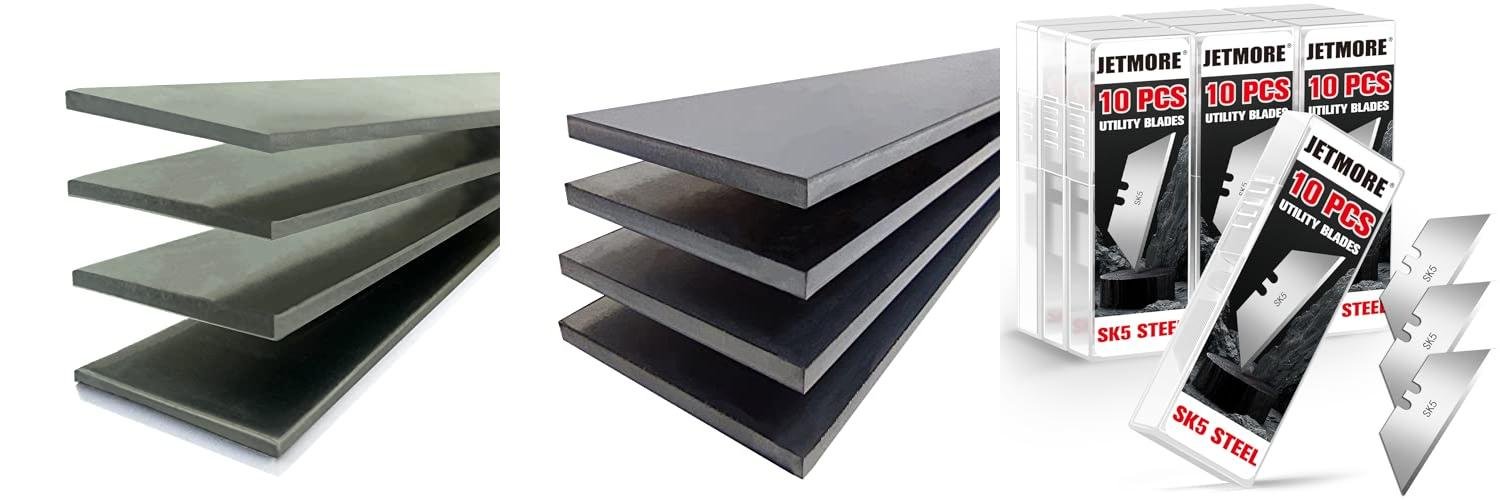

1. 1095 Steel Flat Stock for Knife Making-Annealed High Carbon Steel

Rating: 8.7/10

Get ready to craft your next masterpiece with this 1095 Steel Flat Stock. This pack comes with four pieces of high-quality, annealed high carbon steel, perfect for knife making and other DIY projects. Each bar measures 12 inches long, 1.5 inches wide, and 0.12 inches thick. The cold-rolled and annealed treatment makes these bars easier to work with, saving you time and effort when sanding. You’ll love how well they heat treat, giving you excellent results for your handmade blades and tools.

What We Like:

- Excellent for knife making and hand tools.

- Annealed for easier grinding and shaping.

- 1095 steel offers great heat treatment results.

- Comes in a convenient 4-pack.

- Super tough and grinds beautifully.

- Carefully packaged to prevent rust and damage.

What Could Be Improved:

- The 0.12-inch thickness might be a bit thin for some very heavy-duty applications.

- While the packaging is good, keeping a close eye on it during transit is always wise.

This 1095 steel flat stock is a fantastic choice for anyone looking to create durable and well-performing blades. Its ease of use and high-quality material make it a joy to work with for your DIY projects.

2. 4 Pack 12″x1.5″x0.12″ 1095 Steel for Knife Making with Strict Quality Standards

Rating: 8.9/10

Unleash your inner bladesmith with this 4 Pack of 1095 steel flat stock, designed for both seasoned professionals and enthusiastic hobbyists. Each bar measures a generous 12 inches long, 1.5 inches wide, and 0.12 inches thick. This high-carbon steel is renowned in the knife-making community and is a top pick for creating durable, high-performance knives. Get ready to craft your own custom blades that are built to last!

What We Like:

- This 1095 steel is a top choice for knife making. Many famous makers use it.

- It has great toughness and grinds well. This makes it perfect for DIY knives.

- The steel is cold-rolled and annealed. This makes it easier to work with.

- You save time and abrasive belts when you use this steel.

- You get four bars, which is plenty of steel for your projects.

- The packaging is excellent. It has three layers to stop rust and damage.

- The company cares about your satisfaction. They offer good after-sales service.

What Could Be Improved:

- While the steel is great for making knives, it’s not intended for other uses.

- The strict quality standards mean you’re paying for premium material, which might be a consideration for budget projects.

This 1095 steel offers excellent quality and ease of use for anyone looking to create their own knives. You’ll be happy with the results of your handmade creations.

3. JETMORE 100 Pack Utility Knife Blades

Rating: 9.4/10

Tackle any cutting job with confidence using the JETMORE 100 Pack Utility Knife Blades. These sharp, heavy-duty blades are made from tough SK5 steel, meaning they last longer and cut through tough materials like drywall, carpet, and rope with ease. The standard size fits most utility knives, making them a versatile choice for both pros and DIYers.

What We Like:

- Made from strong SK5 steel for extra durability and longer-lasting sharpness.

- Cuts through many tough materials like carpet, drywall, and rope easily.

- Fits most standard utility knives and box cutters.

- Blades are very sharp, making cuts clean and reducing effort.

- Comes with a safe storage box to keep blades organized and protected.

- Trusted quality for construction, warehouse work, or home projects.

What Could Be Improved:

- For very fine detail work, a specialized blade might be preferred, though these are excellent for general use.

With 100 blades and a safe storage box, this Jetmore pack offers excellent value and reliability for all your cutting needs. Cut smarter and safer with these dependable blades.

4. WORKPRO Utility Knife Blades

Rating: 9.2/10

Tired of dull blades slowing you down? The WORKPRO Utility Knife Blades, SK5 Steel, 100-Pack with Dispenser is your solution for tackling tough jobs with ease. This massive pack ensures you’ll have sharp blades ready whenever you need them.

What We Like:

- Super sharp SK5 steel blades cut through many materials without a struggle.

- They fit most standard utility knives, making them super versatile.

- You get 100 blades in a handy case, which is a great deal for the price.

- The case keeps blades safe for storage and disposal.

- WORKPRO provides a helpful video to show you how to use the dispenser easily.

- These blades are built to last and stay sharp.

What Could Be Improved:

- You really should watch the video to get the most out of the dispenser.

- The blades are so sharp, you need to be careful when handling them.

If you need reliable and affordable replacement blades, this 100-pack from WORKPRO is an excellent choice. You’ll be ready for any cutting task that comes your way.

5. DIYSELF 50 Pack Utility Knife Blades

Rating: 9.2/10

Tired of dull blades slowing you down? The DIYSELF 50 Pack Utility Knife Blades are here to help. These SK5 steel blades are designed for sharp, smooth cutting, making them perfect for all sorts of tasks around the house, office, or even on a job site. They fit standard box cutters and utility knives, so you can easily swap them out when you need a fresh edge.

What We Like:

- Sharp Cutting Power: The blades are polished for quick and smooth cuts through cardboard, rubber, carpet, leather, wallpaper, plastic, and PVC.

- Durable SK5 Steel: Made from SK5 alloy steel, these blades are harder, more wear-resistant, and last longer than regular blades.

- Universal Fit: They are a standard size and work as replacement blades for most box cutters and utility knives.

- Convenient Dispenser: The 50 blades come in a handy box that makes them easy to carry, use, and store.

- Versatile Use: Great for home, office, warehouses, and construction sites, boosting your work efficiency.

What Could Be Improved:

- Initial Sharpness:** While sharp, some users might want an even sharper edge for very delicate materials.

- Blade Thickness:** The 0.6mm thickness is standard, but for extremely tough materials, a slightly thicker blade might be preferred.

These DIYSELF blades offer excellent value and performance for anyone who needs reliable cutting tools. They are a smart buy for keeping your projects moving smoothly.

Choosing the Right Steel for Your Knife Blade

So, you’re looking for a new knife, or maybe you’re curious about what makes one blade better than another. The secret often lies in the steel! Steel is the metal used to make knife blades, and different kinds of steel offer different strengths. This guide will help you understand what to look for.

What Makes Steel Good for Knives?

Good knife steel needs to be strong, hold an edge well, and resist rust. It also shouldn’t be too brittle, meaning it won’t easily break or chip.

Key Features to Look For

When you’re checking out knives, keep these features in mind:

- **Hardness:** This tells you how well the steel can hold a sharp edge. Harder steel stays sharp longer, but can sometimes be more brittle.

- **Toughness:** This is how well the steel can resist chipping or breaking. A tough knife can handle harder tasks without damage.

- **Corrosion Resistance:** This is how well the steel fights off rust. Knives that resist rust are easier to care for, especially if you use them around water.

- **Edge Retention:** This is how long the blade stays sharp. Good edge retention means you won’t have to sharpen your knife as often.

Important Materials in Knife Steel

Knife steel isn’t just plain iron. It’s usually a mix of iron and carbon, plus other elements that give it special properties.

- **Carbon:** This is the most important element. More carbon generally means harder steel and better edge retention.

- **Chromium:** This element helps prevent rust. Knives with more than 13% chromium are considered “stainless steel.”

- **Vanadium:** This makes the steel stronger and helps it hold a sharp edge better.

- **Molybdenum:** This helps the steel resist softening at high temperatures and makes it tougher.

Factors That Improve or Reduce Quality

How the steel is made and treated matters a lot.

What Makes Steel Better:

- **Heat Treatment:** This is a special heating and cooling process that makes the steel harder and tougher. A good heat treatment is crucial for performance.

- **Alloying:** Adding different elements like vanadium or molybdenum can greatly improve the steel’s properties.

- **Forging:** This is a process where the steel is heated and hammered into shape. Forged blades are often stronger and more refined.

What Can Make Steel Worse:

- **Poor Heat Treatment:** If the steel isn’t heated and cooled correctly, it won’t perform as well.

- **Low Carbon Content:** Steel with too little carbon won’t be able to get very hard or hold an edge well.

- **Impurities:** Small bits of unwanted material in the steel can weaken it.

User Experience and Use Cases

The best steel for you depends on how you plan to use your knife.

- **Everyday Carry (EDC) Knives:** These knives are for general tasks like opening packages or cutting rope. Knives with good edge retention and decent corrosion resistance are popular here. Many stainless steels work well.

- **Kitchen Knives:** You want a knife that holds a very sharp edge for slicing food. High carbon stainless steels are common because they offer sharpness and rust resistance.

- **Outdoor and Survival Knives:** These knives need to be tough and reliable. They might be used for chopping wood or prying. High carbon steels or tougher stainless steels are good choices.

- **Collecting Knives:** Some collectors prefer knives made from traditional high carbon steels that can achieve extreme sharpness, even if they require more maintenance to prevent rust.

Understanding these basics will help you pick a knife that’s perfect for your needs!

Frequently Asked Questions (FAQ) about Knife Blade Steel

Q: What is the difference between stainless steel and carbon steel?

A: Stainless steel has chromium added to resist rust. Carbon steel has more carbon and can get harder, but it rusts more easily.

Q: Is harder steel always better?

A: Not necessarily. Harder steel holds an edge longer, but it can also be more brittle and chip more easily. You need a balance of hardness and toughness.

Q: What does “high carbon stainless steel” mean?

A: It means the steel has a good amount of carbon for sharpness and edge retention, plus enough chromium to resist rust.

Q: How often do I need to sharpen my knife?

A: It depends on the steel and how you use the knife. Knives with good edge retention need sharpening less often.

Q: Can I use my kitchen knife outdoors?

A: You can, but outdoor knives are often made of tougher steel. Kitchen knives might get damaged if used for heavy tasks.

Q: What is “patina” on a knife blade?

A: Patina is a natural coating that forms on some carbon steels when they react with food or the air. It can actually help protect the steel from rust.

Q: Is Damascus steel real steel?

A: Damascus steel is made by layering different steels together and folding them many times. It looks beautiful and can be very strong and sharp.

Q: What is the best steel for a beginner?

A: A good quality stainless steel that is easy to sharpen and doesn’t rust easily is a great choice for beginners.

Q: What does ” Rockwell hardness” mean?

A: Rockwell hardness is a number that measures how hard the steel is. Higher numbers usually mean harder steel.

Q: How do I take care of my knife blade?

A: Always clean and dry your knife after use. For carbon steel knives, you might need to oil them to prevent rust.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Larry Fish, the mind behind MyGrinderGuide.com.. With a passion for all things kitchen appliances, I created this blog to share my hands-on experience and expert knowledge. Whether it’s helping you choose the right tools for your culinary adventures or offering tips to make your kitchen more efficient, I’m here to guide you. My goal is to make your time in the kitchen not only easier but also enjoyable! Welcome to my world of kitchen mastery!