Imagine holding a perfectly balanced knife, sharp enough to slice through anything with ease. But what makes that blade so special? It all starts with the steel. Choosing the right steel for your knife is like picking the right building blocks for a strong house. Get it wrong, and your knife might be dull, brittle, or even rust quickly. It’s a common puzzle for anyone wanting to create their own blade or just understand what makes a good knife great.

The world of knife steel can feel like a maze. You hear about different numbers and names, and it’s tough to know which one is best for your needs. Will it hold an edge? Will it be easy to sharpen? Will it survive tough jobs without breaking? These are the real questions that can make your head spin. Many people feel lost when faced with so many choices, and that’s perfectly normal.

But don’t worry! By the end of this post, you’ll understand the secrets behind different knife steels. We’ll break down what makes one steel better than another, so you can confidently pick the perfect material for your next project or simply be a more informed knife enthusiast. Get ready to unlock the mystery of steel and discover what makes a knife truly exceptional.

Our Top 5 Steel To Make A Knife Recommendations at a Glance

Top 5 Steel To Make A Knife Detailed Reviews

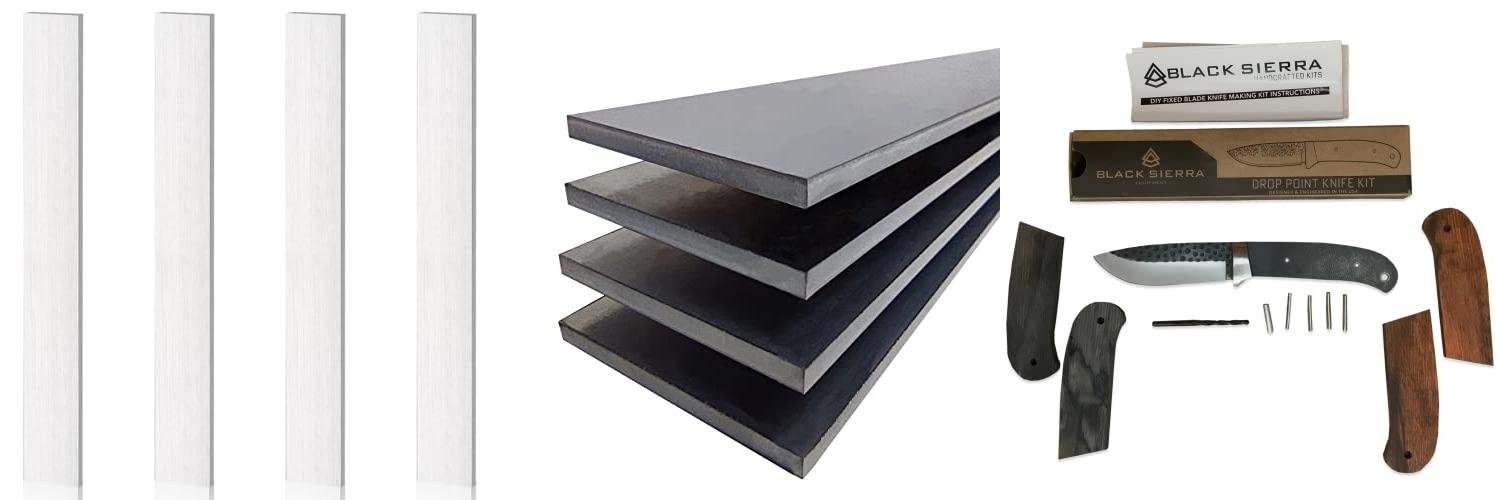

1. ZAVOOS 4 Pack 1095 Steel Flat Stock

Rating: 9.3/10

Are you ready to craft your own blades? The ZAVOOS 4 Pack 1095 Steel Flat Stock offers exactly what you need. This set of high-carbon steel bars is designed for makers, from serious hobbyists to professionals. You get four pieces, each measuring 12 inches long, 1.5 inches wide, and 0.12 inches thick. They are perfect for making knives, tools, and more. This steel is known for being strong and tough, so your creations will last.

What We Like:

- Made from premium 1095 steel, which is very hard and resists wear.

- The steel has good flexibility and toughness, so it won’t easily break or bend.

- It’s cold rolled and annealed, making it easier to work with and saving you effort.

- You can use it for many projects, like making knife blades or even for building things.

- The surface is smooth and pre-oiled, which helps you grip it better.

What Could Be Improved:

- The oil coating, while helpful for grip, might need to be cleaned off before certain finishing processes.

- While good for many uses, the 0.12-inch thickness might be too thin for some heavy-duty forging applications.

These steel bars are a solid choice for anyone wanting to make their own durable tools and blades. They provide the quality material you need to bring your projects to life.

2. 4 Pack 12″x1.5″x0.12″ 1095 Steel for Knife Making with Strict Quality Standards

Rating: 8.5/10

This 4 Pack of 1095 Steel is a fantastic choice for anyone looking to make their own knives. It’s the steel many famous knife makers use. This steel is really tough and sharpens well. It’s perfect for making your own custom knives, whether you’re a pro or just starting out.

What We Like:

- This 1095 steel is the best for making knives. It’s super tough and sharpens easily.

- The steel is annealed, which means it’s softer and easier to work with. This saves you time and wear on your tools.

- You get four bars of steel, each measuring 12 inches long, 1.5 inches wide, and 0.12 inches thick. That’s plenty of material to create your own knives.

- The steel comes with great packaging. It has three layers of protection to keep it safe from rust and damage.

- The company offers good after-sales service. They want you to be happy with your purchase.

What Could Be Improved:

- While the steel is easy to machine, some beginners might still find working with high-carbon steel a bit challenging at first.

- The description mentions “strict quality standards,” but doesn’t detail what those are. More specific information could be helpful.

Overall, this 1095 steel is a top-notch material for creating durable and high-quality knives. It’s a great investment for any knife-making enthusiast.

3. Black Sierra Skinner DIY Knife Making Kit – Stainless Steel Hammered Finish Fixed Blade for Hunting

Rating: 8.7/10

Unleash your inner craftsman with the Black Sierra Skinner DIY Knife Making Kit! This kit lets you build your very own high-quality fixed-blade knife. It’s perfect for anyone who loves a hands-on project and enjoys creating something useful and beautiful. Imagine the satisfaction of using a knife you made yourself on your next outdoor adventure.

What We Like:

- The blade is made of strong, hammered-finish stainless steel that won’t rust and stays sharp.

- You get two beautiful pakka wood handle options to make your knife truly unique.

- This knife is built for many tasks, like hunting, fishing, camping, or just everyday use.

- It’s a fantastic gift idea for anyone who likes to build things or spend time outdoors.

- The kit provides a rewarding and fun project for holidays or birthdays.

What Could Be Improved:

- You’ll need to have a vise, epoxy, files, and sandpaper to put it together.

- The kit doesn’t come with detailed step-by-step instructions, so some research might be needed for beginners.

This kit offers a fantastic opportunity to create a durable, personalized knife. It’s a gift that keeps on giving, providing both the joy of creation and a reliable tool for years to come.

4. 8 Pack 12″x1.5″x0.12″ 1095 Steel for Knife Making with Strict Quality Standards

Rating: 9.0/10

Ready to craft your own custom knives? This 8-pack of 12″x1.5″x0.12″ 1095 steel is designed for both seasoned knife makers and enthusiastic hobbyists. Known for its excellent toughness and ability to hold a sharp edge, 1095 steel is a top choice for many professional knife manufacturers. This annealed high carbon steel makes your DIY knife-making projects more manageable, saving you time and effort.

What We Like:

- High-quality 1095 steel is a favorite among knife makers for its toughness and sharpness.

- The steel is annealed, which makes it easier to work with and machine.

- Each bar is 12 inches long, 1.5 inches wide, and 0.12 inches thick, providing ample material for multiple knife projects.

- The packaging uses three layers of protection (rust-proof oil, paper, and bubble wrap) to ensure the steel arrives in excellent condition.

- The company offers good after-sales support, promising to resolve any issues if you’re not satisfied.

What Could Be Improved:

- The product title is quite long and could be shortened for easier reading.

- While the steel is described as having “strict quality standards,” specific details about these standards are not provided.

This 1095 steel offers a fantastic starting point for anyone looking to create durable, custom knives. With careful craftsmanship, your handmade knives will be built to last.

5. Patriot Steel 1095 High Carbon Knife Making & Forging Steel – Cold Rolled Annealed Steel for Knife Making Supplies – USA-Milled Excellence for Pros & Hobbyists – 12″x1.5″x.187-4 Pack

Rating: 9.1/10

This Patriot Steel 1095 High Carbon Knife Making & Forging Steel is a top-notch material for anyone looking to craft their own knives. It’s cold-rolled and annealed, meaning it’s ready to go with less work. This steel is made in the USA and is built for quality, whether you’re a seasoned pro or just starting out.

What We Like:

- Made in the USA with exceptional quality 1095 steel.

- Consistent product every time thanks to small batch production and strict checks.

- Cold Rolled Annealed (CRA) steel saves you time and sanding belts.

- Great for both professional knife makers and hobbyists.

- You can trust in American craftsmanship.

What Could Be Improved:

- Availability might be limited due to small batch production.

- The price point might be higher than imported options.

If you want reliable, high-quality steel for your knife-making projects, Patriot Steel is a solid choice. It makes crafting easier and delivers excellent results.

Choosing the Right Steel for Your Knife: A Beginner’s Guide

Picking the perfect steel for a knife can seem tricky. But don’t worry, this guide will help you understand what makes a good knife steel. We’ll cover the important things to look for so you can make a great choice.

1. Key Features to Look For

When you’re looking at steel for a knife, a few things stand out. These features help determine how well your knife will work and how long it will last.

- Hardness: This is how well the steel resists scratching and wear. Harder steel holds a sharp edge longer.

- Toughness: This is how well the steel resists chipping or breaking. A tough knife can handle harder use.

- Corrosion Resistance: This is how well the steel fights off rust. Stainless steel is known for this.

- Edge Retention: This is how long the knife’s edge stays sharp. Good edge retention means less sharpening.

- Ease of Sharpening: Some steels are easier to sharpen than others. This is important for keeping your knife in good shape.

2. Important Materials and What They Mean

Knife steels are not just plain iron. They are special mixes of metals. These mixes give the steel its unique strengths.

- Carbon: More carbon usually means a harder steel. This helps with edge retention.

- Chromium: This is a key ingredient for making steel “stainless.” It helps prevent rust.

- Molybdenum: This adds toughness and helps the steel resist softening at high temperatures.

- Vanadium: This makes small, hard particles that improve wear resistance and edge retention.

- Nickel: This can improve toughness and corrosion resistance.

Different steels have different amounts of these elements. For example, high-carbon steels have a lot of carbon. Stainless steels have a lot of chromium.

3. Factors That Affect Quality

Not all steel is created equal. Several things can make steel better or worse for knives.

- Heat Treatment: This is a crucial step. How the steel is heated and cooled changes its hardness and toughness. A good heat treatment makes a big difference.

- Manufacturing Process: How the steel is made matters. Some modern methods create more even and consistent steel.

- Alloying Elements: As we saw above, the types and amounts of other metals mixed with iron are very important.

- Grain Structure: This refers to how the metal’s tiny parts are arranged. A fine grain structure usually means a stronger, tougher steel.

Poor heat treatment can ruin even good steel. Similarly, well-made steel with the right heat treatment will perform much better.

4. User Experience and Use Cases

The best steel for you depends on how you plan to use your knife.

- Everyday Carry (EDC) Knives: These knives are for daily tasks. They need a good balance of sharpness, toughness, and corrosion resistance. Steels like 8Cr13MoV or Sandvik 14C28N are popular choices.

- Outdoor and Survival Knives: These knives face tougher jobs. They need to be very tough and able to hold an edge through hard use. Think about steels like D2 or CPM-3V.

- Kitchen Knives: These knives need to be very sharp and easy to clean. Stainless steels are common here because they resist rust and stains. Steels like VG-10 or AUS-8 are often used.

- Collectors’ Knives: For display, appearance might be more important. However, high-performance steels are still valued for their quality.

Consider what you will cut and how often. This will guide you to the right steel for your needs.

Frequently Asked Questions (FAQ)

Q: What is the most important thing to look for in knife steel?

A: It’s a balance! Hardness, toughness, and corrosion resistance are all very important. The best choice depends on how you’ll use the knife.

Q: Is stainless steel always the best?

A: Not always. Stainless steel resists rust very well, but some high-carbon steels can hold a sharper edge for longer. It depends on what you need.

Q: What does “heat treated” mean for steel?

A: It means the steel was heated and cooled in a special way. This makes it harder and tougher, which is good for a knife.

Q: Will cheaper steel make a bad knife?

A: Not necessarily. Some affordable steels can still make good knives, especially with good design and heat treatment. However, premium steels often offer better performance.

Q: How can I tell if a knife has good steel?

A: Look at the steel type listed by the manufacturer. Research that steel to see its properties. Read reviews from other users.

Q: What is “edge retention”?

A: Edge retention is how long a knife’s edge stays sharp before it needs to be sharpened again.

Q: Is it hard to sharpen tough steel?

A: Sometimes, very tough steels can be a bit harder to sharpen. But they also stay sharp longer, so you won’t have to sharpen them as often.

Q: What are common stainless steel types?

A: Common ones include 440C, 154CM, VG-10, and Sandvik 14C28N. They all offer good rust resistance.

Q: What are common high-carbon steel types?

A: Popular choices are 1095, D2, and A2. These steels can get very hard and hold a sharp edge well.

Q: Should I worry about the steel’s country of origin?

A: While some countries are known for great steel production, the specific steel grade and how it’s treated are more important than just the country.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Larry Fish, the mind behind MyGrinderGuide.com.. With a passion for all things kitchen appliances, I created this blog to share my hands-on experience and expert knowledge. Whether it’s helping you choose the right tools for your culinary adventures or offering tips to make your kitchen more efficient, I’m here to guide you. My goal is to make your time in the kitchen not only easier but also enjoyable! Welcome to my world of kitchen mastery!