Can I remove a grinder blade without the proper wrench? Yes, it is possible to remove a grinder blade without a wrench, but it requires caution and alternative methods. This guide will show you safe and quick ways to remove a stuck grinder disc, including alternative grinder blade removal methods.

Angle grinders are powerful tools, but changing their blades can sometimes be a challenge, especially when the wrench is missing or the blade is stuck. Forced attempts can damage the grinder or, even worse, cause injury. This article will cover the necessary steps to safely and efficiently remove a grinder blade without the standard wrench.

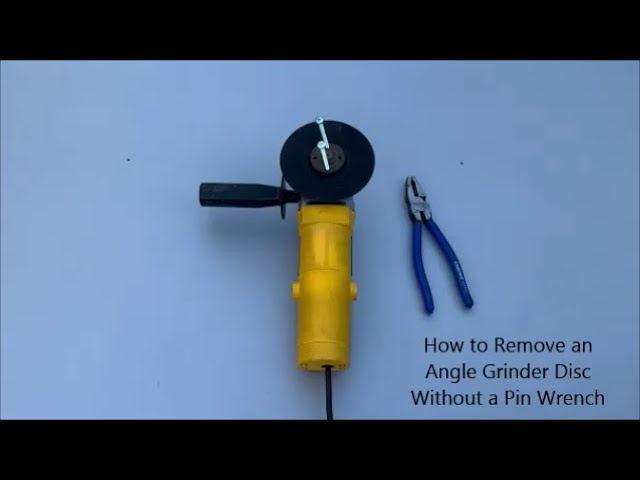

Image Source: i.ytimg.com

Safe Practices Before Beginning

Safety is paramount when dealing with power tools. Before trying any grinder blade removal hacks, remember these safety measures:

- Unplug the Grinder: The most crucial step! Make sure the grinder is disconnected from the power source to prevent accidental starts.

- Wear Safety Gear: Always wear safety glasses, gloves, and a dust mask. Grinding debris can be harmful.

- Inspect the Blade: Check the blade for damage. If the blade is cracked or chipped, handle it with extra care.

- Work in a Clear Area: Ensure your workspace is free of obstacles and has good lighting.

- Read the Manual: Take a moment to look over your grinder’s manual for any specific instructions or warnings related to blade removal.

Why Blades Get Stuck: Common Causes

Before diving into the solutions, let’s see why your grinder disc removal tricks aren’t working. Often, a stuck blade is due to one of the following:

- Over-tightening: The blade was initially tightened too much.

- Rust and Corrosion: Moisture can cause rust, seizing the blade to the spindle.

- Debris Accumulation: Grinding debris can get stuck between the blade and the grinder.

- Heat Expansion: Heat generated during grinding can cause the blade and spindle to expand and bind.

Methods for Removing a Grinder Blade Without a Wrench

If you’re having trouble getting the blade off your grinder, here are a few other ways you can try to get it loose. Just remember to be very careful and pick the method that feels the safest and easiest for you to do.

Method 1: Using Pliers

Pliers are a common household tool and can be effective in some cases.

- Secure the Grinder: Place the grinder in a vise or clamp it to a stable surface.

- Wear Gloves: Protect your hands with sturdy work gloves.

- Position the Pliers: Grip the edge of the locking nut with the pliers. Try to get a firm hold.

- Apply Pressure: Gently try to loosen the nut. If it’s stuck, try moving it back and forth slightly.

- Use the Spindle Lock: While applying pressure with the pliers, engage the spindle lock. This will keep the spindle from rotating.

- Loosen and Remove: Once the nut loosens, you should be able to unscrew it by hand. Remove the blade carefully.

Pros:

- Pliers are readily available.

- Can provide a good grip on the locking nut.

Cons:

- Risk of damaging the locking nut if not careful.

- May not work on very tightly stuck blades.

Method 2: Using a Screwdriver and Hammer

This method uses impact to loosen the nut. This can be a DIY grinder blade removal technique.

- Secure the Grinder: Again, secure the grinder in a vise or clamp.

- Position the Screwdriver: Place the tip of a flathead screwdriver against one of the notches on the locking nut.

- Tap with Hammer: Gently tap the end of the screwdriver with a hammer. Tap in the direction that would loosen the nut.

- Rotate and Repeat: Rotate the screwdriver to another notch and repeat the tapping. Continue until the nut starts to loosen.

- Use Spindle Lock: Engage the spindle lock while tapping.

- Unscrew by Hand: Once loosened, unscrew the nut by hand and remove the blade.

Pros:

- Good for breaking loose stubborn nuts.

- Screwdrivers and hammers are common tools.

Cons:

- Risk of damaging the locking nut or spindle.

- Requires careful and controlled tapping.

Method 3: Using a Strap Wrench

A strap wrench provides a good grip without damaging the nut. This is a great way to loosen grinder blade.

- Secure the Grinder: Secure the grinder in a vise or clamp.

- Position the Strap Wrench: Wrap the strap of the wrench around the locking nut.

- Tighten the Strap: Tighten the strap to get a firm grip on the nut.

- Apply Pressure: Apply pressure to the wrench in the direction that would loosen the nut.

- Use Spindle Lock: Use the spindle lock to keep the spindle from rotating.

- Loosen and Remove: Once loosened, unscrew the nut by hand and remove the blade.

Pros:

- Provides a strong grip without damaging the nut.

- Effective for tightly stuck blades.

Cons:

- Strap wrenches may not be readily available in every household.

- Requires some technique to use effectively.

Method 4: Heat Application

Heat can help loosen a stuck nut by causing the metal to expand. This is one of the more advanced grinder blade stuck solutions.

- Apply Heat: Use a heat gun or hairdryer to apply heat to the locking nut. Be careful not to overheat the surrounding parts.

- Wear Gloves: Wear heat-resistant gloves to protect your hands.

- Try to Loosen: After heating, try to loosen the nut using pliers or another method.

- Repeat if Needed: If the nut is still stuck, repeat the heating process.

- Unscrew by Hand: Once loosened, unscrew the nut by hand and remove the blade.

Pros:

- Effective for rust and corrosion.

- Can loosen very stubborn nuts.

Cons:

- Risk of damaging the grinder if overheated.

- Requires a heat source.

- Need to be very careful

Method 5: Using Penetrating Oil

Penetrating oil can help dissolve rust and corrosion, making it easier to remove the blade.

- Apply Penetrating Oil: Spray penetrating oil (like WD-40 or similar) around the locking nut and spindle.

- Let it Soak: Allow the oil to soak for at least 15-30 minutes. This will give it time to penetrate the rust and corrosion.

- Try to Loosen: After soaking, try to loosen the nut using pliers or another method.

- Repeat if Needed: If the nut is still stuck, repeat the oil application and soaking process.

- Unscrew by Hand: Once loosened, unscrew the nut by hand and remove the blade.

Pros:

- Effective for rust and corrosion.

- Easy to apply.

Cons:

- Requires time for the oil to soak.

- May not work on very tightly stuck blades.

Method 6: Leverage with a Metal Bar

This method provides extra torque to loosen the nut. It is an effective way to learn how to loosen grinder blade.

- Secure the Grinder: Secure the grinder in a vise or clamp.

- Use Pliers or Wrench: Grip the locking nut with pliers or a small wrench.

- Attach Metal Bar: Attach a metal bar (like a pipe or extension) to the handle of the pliers or wrench to extend its length.

- Apply Pressure: Apply pressure to the metal bar to loosen the nut.

- Use Spindle Lock: Engage the spindle lock while applying pressure.

- Unscrew by Hand: Once loosened, unscrew the nut by hand and remove the blade.

Pros:

- Provides extra torque for stubborn nuts.

- Relatively simple to set up.

Cons:

- Risk of damaging the locking nut or pliers/wrench.

- Requires a metal bar or pipe.

Method 7: The Two-Pliers Technique

This method provides balanced pressure to loosen the nut. This can be a useful grinder disc removal trick.

- Secure the Grinder: Secure the grinder in a vise or clamp.

- Position the Pliers: Place one pair of pliers on one side of the locking nut and another pair on the opposite side.

- Apply Pressure: Apply equal pressure with both pairs of pliers to loosen the nut.

- Use Spindle Lock: Engage the spindle lock while applying pressure.

- Unscrew by Hand: Once loosened, unscrew the nut by hand and remove the blade.

Pros:

- Provides balanced pressure.

- Reduces the risk of damaging the nut.

Cons:

- Requires two pairs of pliers.

- May not work on very tightly stuck blades.

Method 8: Using a Rubber Jar Opener

A rubber jar opener can provide additional grip on the locking nut.

- Secure the Grinder: Secure the grinder in a vise or clamp.

- Wrap the Opener: Wrap the rubber jar opener around the locking nut to get a better grip.

- Apply Pressure: Apply pressure to the jar opener to loosen the nut.

- Use Spindle Lock: Engage the spindle lock while applying pressure.

- Unscrew by Hand: Once loosened, unscrew the nut by hand and remove the blade.

Pros:

- Provides enhanced grip.

- Reduces risk of damage.

Cons:

- May not be strong enough.

- Requires access to a rubber jar opener

Table: Summary of Blade Removal Methods

| Method | Tools Required | Pros | Cons | Safety Precautions |

|---|---|---|---|---|

| Pliers | Pliers | Readily available, good grip | Risk of damaging the nut, may not work on very tight blades | Wear gloves, secure the grinder |

| Screwdriver and Hammer | Screwdriver, hammer | Good for breaking loose stubborn nuts, common tools | Risk of damaging the nut or spindle, requires careful tapping | Wear safety glasses, secure the grinder, control tapping |

| Strap Wrench | Strap wrench | Strong grip without damaging the nut, effective for tight blades | May not be readily available, requires some technique | Secure the grinder, follow wrench instructions |

| Heat Application | Heat gun or hairdryer | Effective for rust and corrosion, can loosen very stubborn nuts | Risk of damaging the grinder if overheated, requires a heat source | Wear heat-resistant gloves, avoid overheating, work in a well-ventilated area |

| Penetrating Oil | Penetrating oil (WD-40) | Effective for rust and corrosion, easy to apply | Requires time for soaking, may not work on very tight blades | Wear gloves, allow proper ventilation |

| Leverage with a Metal Bar | Pliers or wrench, metal bar | Provides extra torque for stubborn nuts, relatively simple | Risk of damaging the nut or pliers/wrench, requires a metal bar | Secure the grinder, use caution when applying pressure |

| Two-Pliers Technique | Two pairs of pliers | Provides balanced pressure, reduces the risk of damage | Requires two pairs of pliers, may not work on very tight blades | Wear gloves, secure the grinder |

| Rubber Jar Opener | Rubber jar opener | Enhanced grip, Reduces risk of damage | May not be strong enough, Requires access to a rubber jar opener | Secure the grinder |

Preventing Future Problems

Once you’ve successfully removed the blade, here are some tips to prevent it from getting stuck again:

- Don’t Overtighten: When installing a new blade, tighten the locking nut just enough to secure the blade. Overtightening is a common cause of stuck blades.

- Use Anti-Seize Compound: Apply a small amount of anti-seize compound to the spindle threads before installing a new blade. This will help prevent rust and corrosion.

- Regular Maintenance: Clean your grinder regularly to remove debris that can cause the blade to stick.

- Store in a Dry Place: Store your grinder in a dry place to prevent rust and corrosion.

Troubleshooting: What to Do When Things Go Wrong

Even with the best methods, you might encounter issues. Here’s how to handle some common problems:

- Damaged Locking Nut: If the locking nut is damaged, you may need to replace it. Use a suitable replacement from the manufacturer.

- Stripped Spindle Threads: If the spindle threads are stripped, you may need to have the grinder professionally repaired or replaced.

- Blade Won’t Budge: If the blade is extremely stuck, consider taking the grinder to a professional for assistance.

Alternatives to Grinder Blade Removal Wrench

While the methods above are helpful in a pinch, there are alternatives you can consider acquiring:

- Adjustable Pin Wrench: An adjustable pin wrench can be adapted to fit different sized grinder nuts.

- Universal Wrench: Some universal wrenches are designed to work with a variety of fasteners, including grinder nuts.

- Specialty Grinder Wrenches: Look for wrenches specifically designed for angle grinders that provide better grip and leverage.

FAQ: Frequently Asked Questions

- What is the spindle lock for? The spindle lock prevents the spindle from rotating while you loosen or tighten the locking nut.

- Can I use oil to loosen a stuck blade? Yes, penetrating oil can help dissolve rust and corrosion, making it easier to remove the blade.

- Who is responsible if I damage my grinder trying these methods? You are responsible for any damage incurred while attempting these methods. Exercise caution and proceed at your own risk.

- What if the locking nut is completely seized? If the locking nut is completely seized, you may need to seek professional assistance or consider replacing the grinder.

- Is it safe to use a pipe wrench? Using a pipe wrench can provide extra leverage, but it also carries a higher risk of damaging the locking nut. Use with caution.

Conclusion

Removing a grinder blade without the proper wrench can be tricky, but it’s possible with the right techniques and precautions. Remember to prioritize safety, choose the method that best suits your situation, and don’t force anything. With patience and care, you can safely remove even the most stubborn grinder blades. This comprehensive guide gives you the tools to attempt grinder blade removal hacks while keeping you safe!

Hi, I’m Larry Fish, the mind behind MyGrinderGuide.com.. With a passion for all things kitchen appliances, I created this blog to share my hands-on experience and expert knowledge. Whether it’s helping you choose the right tools for your culinary adventures or offering tips to make your kitchen more efficient, I’m here to guide you. My goal is to make your time in the kitchen not only easier but also enjoyable! Welcome to my world of kitchen mastery!